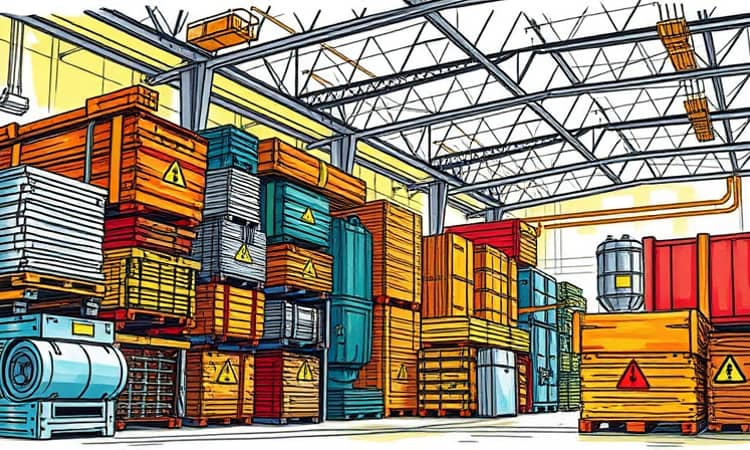

In the world of raw material investments, success often hinges on unseen details.

Beyond price volatility and market trends lies a hidden language of risk defined by fire safety standards.

Understanding commodity classification can transform how you approach investments, turning combustibility risks into strategic insights.

This framework isn't just about storage; it's about safeguarding your portfolio from unexpected costs.

The Hidden Language of Commodity Classification

Commodity classification systems, such as NFPA 13 and the International Fire Code, categorize materials based on combustibility.

These standards were developed to manage fire risks in warehouses and storage facilities.

For investors, this means recognizing that raw material properties directly influence logistics and insurance.

Classes range from noncombustible to high-risk, impacting everything from pile heights to suppression systems.

By mastering this language, you can anticipate supply chain disruptions.

Decoding the Classes: From Noncombustible to High-Risk

The classification system divides commodities into four main classes, each with escalating fire risks.

This table summarizes key details to help investors assess material handling costs.

This classification affects how commodities are stored and insured.

Investors should note that higher fire risk classes often correlate with increased operational expenses.

Real-World Examples: What Belongs Where?

Knowing specific examples helps investors identify risks in their portfolios.

Class I includes materials with minimal fire hazard.

- Cement and gypsum board.

- Metal tools and glass products.

- Fresh fruits in non-plastic trays.

Class II involves items where packaging adds risk.

- Bagged cement or dry foods.

- Alcoholic beverages in combustible containers.

- Free-flowing powders in paper bags.

Class III covers natural materials that are more combustible.

- Wood furniture and plywood.

- Textiles like cotton or wool yarns.

- Paper bags and baled rags.

Class IV includes plastics and mixed goods.

- Plastic-packaged consumer products.

- Oil-based paints in combustible containers.

- Synthetic threads and foam-backed items.

These examples highlight the diversity of raw material investments and their associated risks.

Plastics and Flammables: The High-Stakes Players

Plastics are classified into Groups A, B, and C based on combustibility.

Group A plastics, like ABS, pose the highest fire risk.

Group B includes materials like silicone rubber with moderate risk.

Group C plastics are comparable to wood in hazard level.

- Group A: Requires stringent storage limits.

- Group B: Often mixed in Class IV commodities.

- Group C: Typically allowed in small volumes in Class III.

Flammable liquids, such as motor oil or solvents, add another layer of complexity.

Investors in chemical commodities must account for special handling requirements that drive up costs.

Configuration Matters: How Storage Shapes Risk

Beyond material type, storage configuration significantly impacts fire risk.

High-piled storage increases hazard potential.

Rolled materials like paper or asphalt are often high-risk.

- Vertical storage can limit sprinkler effectiveness.

- Foamed items like mattresses require extra precautions.

- Carousel systems with plastics need enhanced protection.

Understanding these factors helps investors evaluate warehouse efficiency.

Practical steps include assessing storage height limits and suppression system designs.

Investment Implications: Beyond the Warehouse

Fire classification directly influences investment outcomes through costs and risks.

Higher classes demand advanced fire suppression systems.

This can lead to increased insurance premiums.

- Storage costs rise with more stringent safety measures.

- Supply chain vulnerabilities may emerge from compliance issues.

- Long-term value can be affected by material degradability.

Key commodities like wood, plastics, and chemicals are central to many markets.

Investors should consider these factors when trading futures or managing portfolios.

For example, logistics costs for plastics can erode profit margins if not planned for.

Building resilience involves integrating safety data into investment strategies.

This proactive approach can mitigate unexpected disruptions.

Practical Steps for Savvy Investors

To leverage this knowledge, start by researching commodity classifications in your holdings.

Consult with logistics experts on storage best practices.

- Audit your portfolio for high-risk materials like Group A plastics.

- Factor in insurance costs based on fire class data.

- Monitor regulatory changes in fire safety standards.

- Diversify investments to balance risk across classes.

- Engage with suppliers to ensure compliance and cost-efficiency.

By taking these steps, you can turn hidden risks into opportunities for growth.

Empower yourself with data to make informed decisions.

Remember, every raw material tells a story of risk and reward.

Embrace this framework to build a more resilient investment strategy.

Your journey to smarter investing starts with understanding the basics.